Focus On: Crown WAV-60

April 12, 2021

Focus On: RM/RMD 6000

June 14, 2021

Welcome back to our "Focus On" series, today bringing you some info on the latest addition to Toyota's warehousing lineup, the Toyota Reach Truck electric forklifts. Above you can see a picture of the 9BRU, and you can read what Toyota has to say about it here.

One of the most widely used of these is the 9BRU18 with a base capacity of 3500 lbs (1587 kg). This is actually the mid-range capacity for the Reach Truck series, and is one of four truck base capacities available. All told there are 13 versions of the Reach Truck and these are broken down by weight class and battery compartment size, with most of the series using 36V power systems. That count however is counting the 9BRU18 four times; that model comes in 24V and 36V and two different battery compartment sizes. The 9BDRU13 also comes in 24V and two different compartment sizes, while all other models use the higher rated 36V systems.

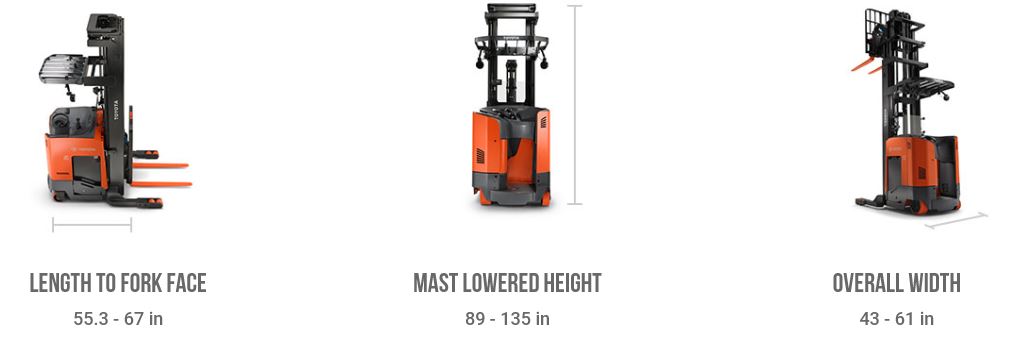

Reach Truck dimensions

Reach deep, real deep!

If you remember our article on Toyota's Stand-up Rider you might recall talk about things like right-angle stack and dock to stock. The Reach Truck takes all those points and lets you cut down on aisle space even more by letting you change how you use your racking system. There's basically two broad brushes for the Reach Truck series. First there's the 9BRU side of things which is the standard reach depth of 28.5" (72 cm), letting you stack a pallet without having to nuzzle your forklift up to the rack. Then there's the 9BDRU (the deep reach build) with a 53.25" (135 cm) maximum reach, letting you fit another pallet behind the first. Assuming your racks are deep enough of course.By the foot - Twenty five tall, eight deep

No talk about forklifts is complete without a discussion of the mast and lift height, so after going over the reach depths that's a natural next point. The Reach Truck series has 31 mast height options spread between the four general truck capacities. All of these are 3 stage, full free-lift (FSV) masts: 9BRU18: 193" (4.9 m) to 301" (7.65 m). 3500 lb (1580 kg) base lift capacity. 9BDRU13: 189" (4.8 m) to 264" (6.71 m). 2500 lb (1134 kg) base lift capacity. 9BRU23: 193" (4.9 m) to 301" (7.65 m). 4500 lb (2040 kg) base lift capacity. 9BDRU15: 189" (4.8 m) to 302" (7.67 m). 3000 lb (1360 kg) base lift capacity. So, much like the Stand-Up Rider before it, you might want to talk to our CSS reps about all your options to find the right truck to fit your operations.

9BDRU15 from the rear

What's it got?

We've talked about lift heights and weights, but what have these machines got beyond a mast and forks? With each of these trucks ranging from 6100 lbs (2767 kg) to 6758 lbs (3065 kg), the extra weight they get from their battery, ranging (again) from 1600lbs (72 kg) to 2900 lbs (1310 kg) lets them lift in a way no gas powered truck with a similar footprint can. Keeping that right angle stack and turn radius down keeps them firmly in the world of narrow aisle trucks, but their ability to reach means they are a class of their own. Something else to keep in mind is that because of that battery, the maintenance these trucks need is very different to a gas truck. If you're familiar with electric warehousing trucks you'll know this already, but you'll never have to worry about engine oil, spark plugs, or air filters ever again. Having to get the batteries means that many electric trucks have a higher initial sticker price, but a lower overall cost to maintain. The bulk of those upkeep costs will show up in the periodic & battery maintenance we suggest to our customers, because if you don't take care of your batteries, they will fail and cost you all that money again. Four separate motors work together to keep this machine moving. Independent drive motors keep the truck rolling, a steer motor to keep you going where you want, and a lift motor to put your load where it needs to be. One of these reasons for all these different motors is the keep the truck's responses consistent; keeping the different systems apart means you never have to worry about one operation causing another to behave unpredictably. Because the very last thing you want is a few of tons of machine being unpredictable. The Reach Truck is built with ergonomics in mind too. Padded back and arm rests help maintain operator comfort, and get replaced with larger versions if you have the dock stance option installed. The floor of the operator compartment is built with a slight slope and 7/8" (2.2cm) foam rubber floor pad to help pad your operator's from the bumps they'll encounter in the warehouse. Getting into that compartment is also nice and easy with a low step height for operators to board the truck.Like the Stand-up Rider before it, that open compartment is actually a key safety feature. Unlike a traditional forklift where an operator would have to scrabble out of a seat and somehow try to make it clear of the machine while it is tipping over, the open compartment and low step make it really easy for an operator to just step off and away from the machine. Building on that human reflex of just stepping back, that instinctive act in the face of danger can keep your people safe. This is especially important considering that tip-overs account for 25% of forklift fatalities.

There's options of course

Toyota lift trucks come with a lot of things standard. The Reach Truck comes with programmable performance parameters, a lowering flow limiter, and hydraulically cushioned mast staging and reach retraction. An integrated cup holder, clipboard, and amenity tray help keeps things close at hand for your operators. Regenerative breaking helps save on power while auto position hold helps protect against roll-back on slight inclines. Self diagnostics with instructional messages help operators troubleshoot basic problems, and fault code memory ensures that trained technicians can quickly find the source of common problems. That isn't the full list of course. For that see what Toyota says. A few of the select options we think are especially useful: Dock Stance - Adds a third pillar to the overheard guard and keeps your operators in place when crossing the dock. Travel alarms, strobes, and LED lighting both unit and mast mounted - seeing where you're working is important after all. Operator PIN code entry activation - to ensure that only those authorized to do so can drive your lift trucks. Acculaser - Means your operator has an easier time seeing where the pallet is going to go. Battery compartment sizes - Do you need more power or more counterweight? Different batteries might do the trick. Tire material and hardness options - you don't want the hardest tire, just the best one for your work. Cold storage conditioning - freezers are brutal on machinery, so protect your investment. Load weight display - It isn't legal for trade, but if you just need an idea for the weight, you'll be good to go. UL-approved EE rating - do your work areas class as Division 2 hazardous? You literally need an EE rated truck. Not all of these options are available for every unit, and some of them are restricted to certain sizes/weights of unit (for example, the 21.25" battery compartment is only available on the 9BDRU15 and the 9BRU23). Some options just don't work well together after all, and Toyota works hard to maintain its delivery of a world class material handling machine, no matter what form it takes.

So there we go: a bit of a breakdown for the Toyota Reach Truck lift trucks, one of the stand out warehouse trucks available on the market. Like always if you want to know more you can always Click Here to see what Toyota says about their product.

Better yet you can Get In Contact with one of our CSS Team Members to learn more about this machine and about your options for outfitting your business with proven dependability and success from Toyota.

Better yet you can Get In Contact with one of our CSS Team Members to learn more about this machine and about your options for outfitting your business with proven dependability and success from Toyota.